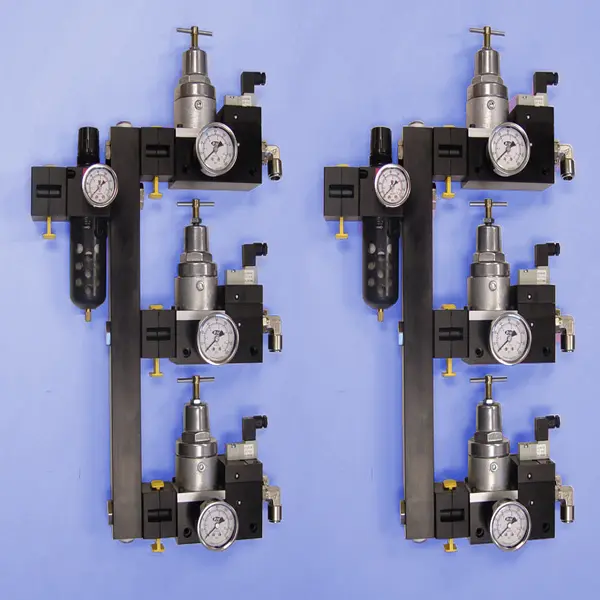

Liquid Pump Control Features Pneumadyne's New Pilot Operated Cartridge Valves

Customer Application:

A manufacturer of liquid pump controls contacted Pneumadyne to re-design their pneumatic circuit. Their existing equipment consisted of numerous fittings, ball valves and individual components which were difficult and time-consuming to assemble and resulted in multiple potential leak-points.

Application Requirements:

- Reduce overall power consumption of the circuit

- Meet specific high flow requirements

- Regulate system pressure

- Reduce the number of potential leak points

- Isolate the individual circuits

Pneumadyne’s Solution:

By integrating components Pneumadyne Engineers were able to eliminate potential leak-points, improve the appearance of the circuit and reduce the customer’s field assembly time and cost.

- Valve blocks feature two of Pneumadyne’s new C500 Pilot Operated Cartridge Valves

- Shut-off blocks are included to isolate the circuitry

- Filter/Regulator

- A single input port supplies pressure to all three circuits

- Inline pressure gauges provide constant input and output pressure reading

- A surface mount Regulator is integrated in the valve block and controls

- Three output ports feature swivel push-to-connect elbows for tubing alignment purposes

- Power consumption was reduced from 12 Watts by using a 1 Watt solenoid as a pilot to operate the internal cartridge valves

- The modular design of the assembly easily accommodates single, double or triple circuits in the customer’s application

Contact us today to review the specifications of your material handling application.

Learn more about custom components from Pneumadyne.

|